- mdi can help!

- The mdi Sales Team is standing by to help you with your order or questions about our Products. Give mdi a Call Today!

- 727-835-0648

- Email our Sales Team

- Office Hours: 7:00 am - 7:00 PM EST M - F

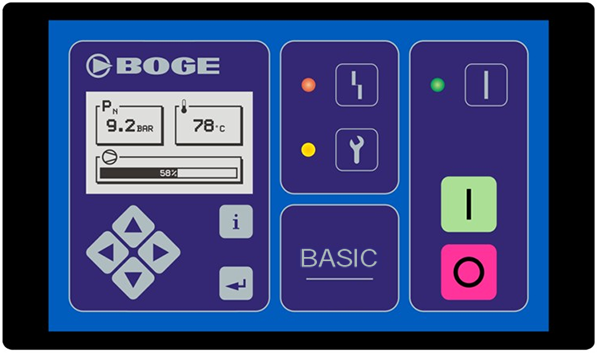

Compressor Controls

Controlling and monitoring according to demand:

The BOGE control and monitoring system operates according to the customer’s actual compressed air demand. Our BASIC and FOCUS controls are designed to ensure simple and reliable control for various operating parameters at two levels. Whilst,the PRIME control is a state-of-the-art energy efficient control intended for use with oil free screw compressors.

- 5 parameters in main display

- In situ software update possible

- Code programmable

- Automatic antifreeze operation

- Auto restart

- Potential-free contacts for messages (retrofittable)

COMPLETE CONTROL

A large-scale back-lit LC display with clear text

information visibly shows error/maintenance

messages, operating states and all operating

parameters. All relevant values are available at

a glance enabling you to specifi cally confi gure

all essential parameters for effi cient operation

of your installation.

COMPLETE DEPENDABILITY

Whether your compressor is due for

maintenance or if your compressed air

network is malfunctioning, the control

display will inform you. This helps to

improve the operating safety of your

compressed air supply and the service

life of all essential component parts.

COMPLETE EFFICIENCY

BOGE compressor controls use a pressure

sensor to control whether or not the requested

pressure in your compressor station has been

achieved. This enables you to preset minimum

and maximum pressures and to control the

operation of your compressor station according

to demand. The state-of-the-art BOGE compressor controls are engineered to meet the latest control requirements and are continuously being improved and optimised – for safe and

efficient operation in all operating conditions.

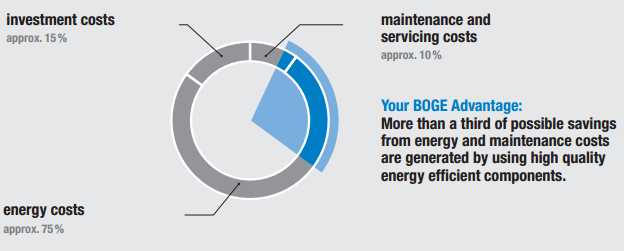

Intelligent Controlling Pays Off

Boge Controls Include the Money Saving Leakage Monitor Featuring:

AUTOMATIC MEASURING

The BOGE leakage monitor is

designed to automatically measure

the operating load times during

times when the compressor is only

operating to make up for the

leakages. Such times are

extrapolated for the whole year

before being displayed.

ONBOARD OR RETROFITTED

On new machines the BOGE leakage monitor is integrated as standard in the BASIC or FOCUS controls. Existing models can be easily retro-fi tted with the leakage module.

FOR SMALLER NETWORKS

The BOGE leakage monitor is intended for dependable leakage monitoring of single compressors or smaller networks of up to 3 compressors. Losses can rapidly add up over the course of the year!

TARGET ORIENTED OPTIMIZATION

The BOGE leakage monitor is engineered to tell you exactly when it is time for action. This enables your BOGE service partner to carry out leakage detection and make the repairs.

No chance for cost guzzlers:

Leakages tend to occur in almost every compressed air network and are responsible for up to 20 percent of compressed air costs. From now, BOGE can take care of this problem on an ongoing basis: the BOGE leakage monitor will automatically measure leakage losses and display the result on the compressor controller. This will enable you to decide when a professional leakage repair should to be carried out: in three easy steps!

- MEASURING

Just before the end of a shift (for example over night or during the weekend ) simply activate the BOGE leakage monitor by means of the control and start it by pressing the enter key. Important: The intended compressed air consumption must be zero, viz. all consumption points to be switched off and only compressors with leckage monitor to be switched on. The BOGE leakage monitor will start measuring the operating load times six hours after initiating which, at this stage, only serves the leakage losses – a total waste of energy. A single measurement operation is carried out over a period of six hours. - READING

Any leakage losses can be read off the controller display on the next working day. The BOGE leakage monitor will extrapolate the losses over the course of a year (123 wasted hours of operation per year, as illustrated in the example). This will enable you to make a commercial decision as to whether the costs resulting from leakage losses are likely to pay back the investment for professional leak detection and subsequent repair. - CUTTING COSTS

The present example is intended to show the amount of costs that can be saved: If the BOGE leakage monitor shows an idle operation time of 350 hours per year, you will pay, based on an electrical power consumption of 24 kW and an electricity price of 0.11 € /kWh, more than 960 Euros just for replenishing your leakage losses – for electricity alone!