- mdi can help!

- The mdi Sales Team is standing by to help you with your order or questions about our Products. Give mdi a Call Today!

- 727-835-0648

- Email our Sales Team

- Office Hours: 7:00 am - 7:00 PM EST M - F

Drypoint RA Refrigerant Air Dryers

Flow Capacity: 800 - 4,000 cfm

Max. Operating Pressure: 200 psig

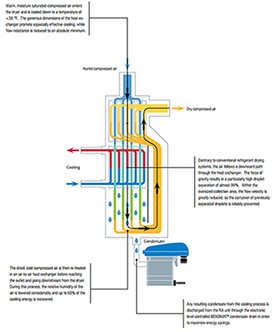

The most efficient method of drying compressed air

When compressed air is cooled near to freezing point, water and oil vapors create condensate. This method of drying is expensive to the end user as it uses energy and creates pressure losses.

Thanks to its energy saving components, the RA series is capable of substantially reducing such costs over the entire lifetime of the compressed air system by combining savings potentials with maximum reliability.

Features

- Reliable pressure dewpoint

the RA series with a built-in Varioflow hot gas bypass valve, provides users with a 100% stable dew point requiring no maintenance and zero freeze-ups - Intelligent design

the specially designed aluminium heat exchanger represents an innovative vertical profile concept that allows the force of gravity to result in high droplet separation and self-cleaning - Low pressure differential

due to the downward path through the aluminium heat exchanger the RA series has extremely low pressure differentials. As a result, the generation pressure upstream of the compressor can be optimized - Environmentally friendly coolant

the R134a refrigerant does not have any ozone depleting characteristics. That, in conjunction with the use of recyclable materials and the built-in energy efficiency provides a truly environmentally friendly product

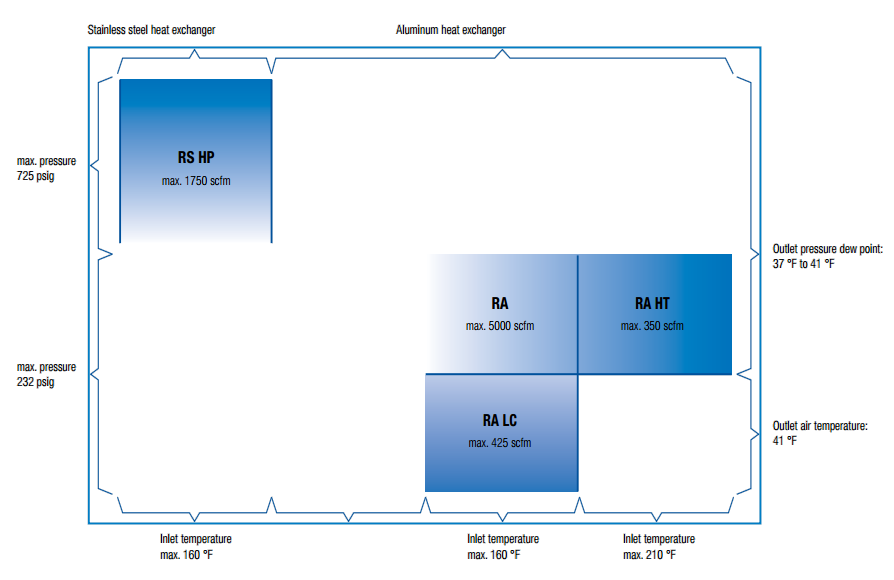

THE RIGHT SOLUTION WHATEVER THE TASK

BOGE is world renowned for its innovative, solution oriented

compressed air technology. Geared to the customers’ needs,

BOGE presents a comprehensive product portfolio, covering air

treatment, condensate technology and process engineering.

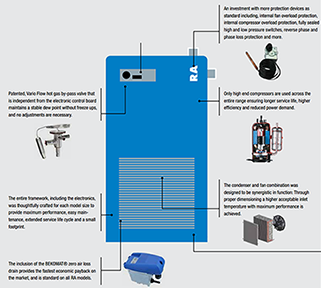

INTEGRATED BEKOMAT DRAIN

Reliable condensate discharge and maximum energy

savings.

RELIABLE PRESSURE DEW POINT

Thanks to their generously designed components, refrigerant dryers

in the BOGE RA series maintain a constant pressure dew point. This

ensures consistently high compressed air quality with a low pressure

differential. All RA dryers are equipped with a pressure dew point

indicator.

MINIMAL PRESSURE LOSS

All RA dryers are characterized by their extremely low pressure

loss. This allows the upstream compressor to deliver less pressure,

thus avoiding overcompensation. Energy savings of six percent are

achieved for every bar of pressure saved – far higher than with other

dryer systems.

MAINTENANCE FRIENDLY

The compact design and open frame provides easy access to all

components.

The most efficient method of drying compressed air:

Compressed air is cooled to just above freezing point which means that water and oil aerosols contained in the air will condense. The two major cost factors involved are energy use and compensating for any pressure loss.

Click to Enlarge

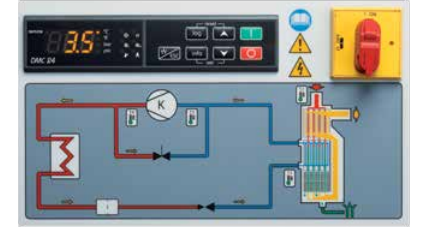

Two Controller Types:

DMC 18 (RA 20 - 500)

- Dewpoint temperature display and LCD display panel

- Condenser fan temperature control

- Adjustable high and low dewpoint alarm

- Potential free alarm contacts

- Displays services and alarms

DMC 24 (RA 600 to 5000)

- Includes all of the above plus:

- Fully programmable from the front panel

- Complete LED status indication

- Working hours metering

- Advanced service warning function

- Advanced alarm management function

- PC or control system connectivity

ENVIRONMENTALLY FRIENDLY COOLANT

The R134a and the R407C coolant used is ozone neutral and, in conjunction with the recyclable materials and the high energy

efficiency, ensures maximum conservation of resources and modern and environmentally compatible refrigerant dryer operation.

| Model | Flow Rate | Pressure Drop | Connection Size | Standard Voltage | Required Pre-Filter | Dimensions (in) | Weight | ||

|---|---|---|---|---|---|---|---|---|---|

| scfm | psid | W | D | H | lbs | ||||

| RA 20 | 20 | 0.44 | ½” NPT-F | 115V / 1Ph | FF30 | 14 | 17 | 29 | 62 |

| RA 30 | 30 | 1.16 | ½” NPT-F | 115V / 1Ph | FF30 | 14 | 17 | 29 | 64 |

| RA 50 | 50 | 1.60 | ½” NPT-F | 115V / 1Ph | FF50 | 14 | 17 | 29 | 75 |

| RA 75 | 75 | 1.89 | 1” NPT-F | 115V / 1Ph | FF80 | 14 | 17 | 29 | 79 |

| RA 100 | 100 | 2.47 | 1 ¼” NPT-F | 115V / 1Ph | FF100 | 19 | 18 | 32 | 82 |

| RA 125 | 125 | 2.18 | 1 ¼” NPT-F | 115V / 1Ph | FF125 | 19 | 18 | 32 | 101 |

| RA 150 | 150 | 2.90 | 1 ¼” NPT-F | 115V / 1Ph | FF160 | 19 | 18 | 32 | 110 |

| RA 200 | 200 | 2.18 | 1 ½” NPT-F | 115V / 1Ph | FF200 | 22 | 23 | 35 | 121 |

| RA 250 | 250 | 2.61 | 1 ½” NPT-F | 230V / 1Ph | FF250 | 22 | 23 | 35 | 139 |

| RA 300 | 300 | 1.31 | 2” NPT-F | 230V / 1Ph | FF500 | 22 | 25 | 38 | 203 |

| RA 350 | 350 | 1.89 | 2” NPT-F | 230V / 1Ph | FF500 | 22 | 25 | 38 | 207 |

| RA 400 | 400 | 1.02 2 | ½” NPT-F | 230V / 1Ph | FF500 | 26 | 29 | 44 | 331 |

| RA 500 | 500 | 1.89 | 2 ½” NPT-F | 460V / 3Ph | FF500 | 26 | 29 | 44 | 355 |

| RA 600 | 600 | 2.47 | 3” Flange | 460V / 3Ph | FF600 | 31 | 39 | 58 | 529 |

| RA 800 | 800 | 3.05 | 3” Flange | 460V / 3Ph | FF800 | 31 | 39 | 58 | 534 |

| RA 1000 | 1000 | 2.76 | 3” Flange | 460V / 3Ph | FF1150 | 31 | 39 | 58 | 608 |

| RA 1250 | 1250 | 3.77 | 3” Flange | 460V / 3Ph | FF1450 | 31 | 39 | 58 | 686 |

| RA 1500 | 1500 | 3.05 | 4” Flange | 460V / 3Ph | FF1750 | 45 | 47 | 69 | 1021 |

| RA 1750 | 1750 | 2.03 | 4” Flange | 460V / 3Ph | FF1750 | 45 | 47 | 69 | 1186 |

| RA 2000 | 2000 | 2.90 | 4” Flange | 460V / 3Ph | FF2100 | 45 | 47 | 69 | 1190 |

| RA 2500 | 2500 | 3.77 | 4” Flange | 460V / 3Ph | L102 | 45 | 47 | 69 | 1349 |

| RA 3000 | 3000 | 2.90 | 6” Flange | 460V / 3Ph | L150 | 51 | 69 | 71 | 1830 |

| RA 4000 | 4000 | 2.90 | 6” Flange | 460V / 3Ph | L156 | 55 | 87 | 74 | 2330 |

| RA 5000 | 5000 | 3.77 | 8” Flange | 460V / 3Ph | L156 | 55 | 87 | 74 | 2650 |

| Standard outlet pressure dew point | 38 °F |

|---|---|

| Max. inlet air temperature | 160 °F |

| Min./max. ambient temperature | 34 °F / 120 °F |

| Max. inlet pressure | |

| RA 20 - 50 | 232 psig |

| RA 75 - 5000 | 200 psig |

| Required Pre-filtration | 1.0 μm |

| Recommended Post-filtration | 0.01 μm |

| Available Dryer Options | Model Sizes |

|---|---|

| 230V / 1 Ph | RA 200 |

| 460V / 3 Ph | RA 200 - RA 400 |

| Water Cooled | RA 600 - 2500 |

| Sea Water Cooled | RA 600 - 2500 |

| Anti-Corrosion Treatment | All model sizes |

| Dryer By-Pass | All model sizes |

Click to Enlarge

The BOGE product family of compressed air refrigeration dryers:

Provides users with several advanced features creating a balanced and efficient drying system.

| Operating Pressure psig | 60 | 80 | 100 | 120 | 140 | 160 | 180 | 200 |

|---|---|---|---|---|---|---|---|---|

| Correction Factor | 0.79 | 0.91 | 1.00 | 1.07 | 1.13 | 1.18 | 1.23 | 1.27 |

| Inlet Temperature °F | 90 | 100 | 110 | 120 | 130 | 140 | 150 | 160 |

|---|---|---|---|---|---|---|---|---|

| Correction Factor | 1.16 | 1.00 | 0.82 | 0.68 | 0.61 | 0.52 | 0.45 | 0.40 |