- mdi can help!

- The mdi Sales Team is standing by to help you with your order or questions about our Products. Give mdi a Call Today!

- 727-835-0648

- Email our Sales Team

- Office Hours: 7:00 am - 7:00 PM EST M - F

Flow Capacity:

11 - 116 cfm

Max. Operating Pressure:

100 - 220 psig

TWIST 60 TECHNOLOGY

Twist 60 represents the unique arrangement

of membrane fibers when winding. Providing

the lowest purge consumption, leading to lower

energy costs.

INTEGRATED COMPRESSED AIR FILTER

A standard intergrated nano compressed air filter is included to provide technically oil free compressed air.

ENERGY EFFICIENT

As the membrane dryer does not have a motor or any moving parts it does not need any additional energy eliminating unnecessary energy costs.

ENVIRONMENTALLY FRIENDLY

The membrane dryer does not contain any CFCs and is therefore neither ozone depleting nor does it have any impact on the environment.

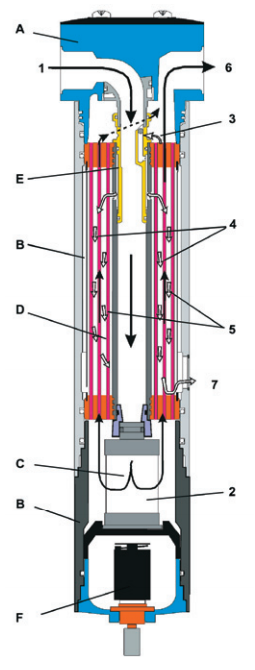

Membrane Dryer Layout

A: Head (inlet / outlet)

B: Filter housing

C: Nano-filter

D: Membrane element including main body

E: Nozzle with adapter

F: Float drain

(1) Saturated compressed air enters via the

dryer cap (A) and flows down the central

tube (D).

(2) The Nano-filter (C) removes

any remaining aerosols and particles,

separated condensate is drained (F). The

saturated compressed air flows through the

inside of the membranes.

(3) A part of the

compressed air is diverted and expands to

atmosphere at the nozzle (E).

(4) This very

dry purge air is lead across the outside of

the membranes (D).

(5) Thus the saturated

compressed air flows on the inside and the

dry purge air on the outside. Due to the

differences in humidity, moisture diffuses

from the compressed air to the purge air.

(6) The dry compressed air exits.

(7) The

purge air escapes to the atmosphere.

Pressure Correction Factors

Pressure dew point reduction in a compact package:

the BOGE memb

| Pressure | 60 | 75 | 90 | 100 | 115 | 130 | 145 | 160 | 175 |

|---|---|---|---|---|---|---|---|---|---|

| Factor | 0.39 | 0.57 | 0.78 | 1.00 | 1.19 | 1.40 | 1.62 | 1.87 | 2.11 |

rane dryer is used where the pressure dew point needs to be reduced between 68 and 130°F. It requires little space and can be installed at minimal cost ideally for point of use dry air.

| Model | Operating Pressure | Dryer Inlet Conditions | Outlet PDP | Purge | Dryer Outlet | Dryer Outlet | Compressed Air Connection | Dimensions H x W x D | Weight | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| bar | psig | pdp inlet | scfm | l/min | scfm | l/min | scfm | in. | lbs. | |||

| DM 02 | 7 | 100 | 100F | 1.83 | 65F | 5.10 | 0.18 | 46.73 | 1.65 | 1/4" | 10.43 x 1.81 x 1.06 | 1.74 |

| 100F | 0.98 | 35F | 4.81 | 0.17 | 22.94 | 0.81 | 1/4" | 10.43 x 1.81 x 1.06 | 1.74 | |||

| 100F | 0.58 | -20F | 4.81 | 0.17 | 11.61 | 0.41 | 1/4" | 10.43 x 1.81 x 1.06 | 1.74 | |||

| DM 04 | 7 | 100 | 100F | 3.66 | 65F | 9.91 | 0.35 | 93.74 | 3.31 | 1/4" | 12.40 x 1.81 x 1.06 | 1.92 |

| 100F | 2.07 | 35F | 9.91 | 0.35 | 48.71 | 1.72 | 1/4" | 12.40 x 1.81 x 1.06 | 1.92 | |||

| 100F | 1.33 | -20F | 9.91 | 0.35 | 27.75 | 0.98 | 1/4" | 12.40 x 1.81 x 1.06 | 1.92 | |||

| DM 06 | 7 | 100 | 100F | 5.49 | 65F | 14.73 | 0.52 | 140.75 | 4.97 | 1/4" | 13.98 x 1.81 x 1.06 | 2.07 |

| 100F | 3.10 | 35F | 14.73 | 0.52 | 73.07 | 2.58 | 1/4" | 13.98 x 1.81 x 1.06 | 2.07 | |||

| 100F | 2.00 | -20F | 14.73 | 0.52 | 41.91 | 1.48 | 1/4" | 13.98 x 1.81 x 1.06 | 2.07 | |||

| DM 07 | 7 | 100 | 100F | 7.32 | 65F | 15.29 | 0.54 | 192.01 | 6.78 | 1/4" | 16.34 x 1.81 x 1.06 | 2.27 |

| 100F | 4.13 | 35F | 15.29 | 0.54 | 97.14 | 3.43 | 1/4" | 16.34 x 1.81 x 1.06 | 2.27 | |||

| 100F | 2.63 | -20F | 15.29 | 0.54 | 59.19 | 2.09 | 1/4" | 16.34 x 1.81 x 1.06 | 2.27 | |||

| DM 10 | 7 | 100 | 100F | 10.45 | 65F | 30.02 | 1.06 | 265.92 | 9.39 | 3/8" | 17.00 x 2.95 x 1.10 | 4.13 |

| 100F | 5.89 | 35F | 30.02 | 1.06 | 136.79 | 4.83 | 3/8" | 17.00 x 2.95 x 1.10 | 4.13 | |||

| 100F | 3.85 | -20F | 30.02 | 1.06 | 79.01 | 2.79 | 3/8" | 17.00 x 2.95 x 1.10 | 4.13 | |||

| DM 11 | 7 | 100 | 100F | 11.00 | 65F | 29.74 | 1.05 | 281.78 | 9.95 | 3/8" | 19.76 x 2.95 x 1.10 | 4.63 |

| 100F | 6.20 | 35F | 31.15 | 1.10 | 144.43 | 5.10 | 3/8" | 19.76 X 2.95 X 1.10 | 4.63 | |||

| 100F | 3.90 | -20F | 31.15 | 1.10 | 79.30 | 2.80 | 3/8" | 19.76 X 2.95 X 1.10 | 4.63 | |||

| DM 15 | 7 | 100 | 100F | 14.60 | 65F | 39.65 | 1.40 | 373.82 | 13.20 | 3/8" | 22.19 x 2.95 x 1.10 | 5.07 |

| 100F | 8.25 | 35F | 39.65 | 1.40 | 193.99 | 6.85 | 3/8" | 22.19 x 2.95 x 1.10 | 5.07 | |||

| 100F | 5.20 | -20F | 39.65 | 1.40 | 107.62 | 3.80 | 3/8" | 22.19 x 2.95 x 1.10 | 5.07 | |||

| DM 22 | 7 | 100 | 100F | 22.00 | 65F | 59.47 | 2.10 | 563.57 | 19.90 | 3/4" | 22.57 x 3.94 x 1.34 | 7.72 |

| 100F | 12.40 | 35F | 59.47 | 2.10 | 291.70 | 10.30 | 3/4" | 22.57 x 3.94 x 1.34 | 7.72 | |||

| 100F | 7.90 | -20F | 59.47 | 2.10 | 164.26 | 5.80 | 3/4" | 22.57 x 3.94 x 1.34 | 7.72 | |||

| DM 30 | 7 | 100 | 100F | 29.30 | 65F | 79.30 | 2.80 | 750.48 | 26.50 | 3/4" | 24.59 x 3.94 x 1.34 | 8.38 |

| 100F | 16.50 | 35F | 79.30 | 2.80 | 387.98 | 13.70 | 3/4" | 24.59 x 3.94 x 1.34 | 8.38 | |||

| 100F | 10.50 | -20F | 79.30 | 2.80 | 218.06 | 7.70 | 3/4" | 24.59 x 3.94 x 1.34 | 8.38 | |||

| DM 39 | 7 | 100 | 100F | 38.30 | 65F | 118.94 | 4.20 | 965.71 | 34.10 | 3/4" | 27.35 x 3.94 x 1.34 | 9.04 |

| 100F | 24.20 | 35F | 118.94 | 4.20 | 566.40 | 20.00 | 3/4" | 27.35 x 3.94 x 1.34 | 9.04 | |||

| 100F | 16.00 | -20F | 118.94 | 4.20 | 334.18 | 11.80 | 3/4" | 27.35 x 3.94 x 1.34 | 9.04 | |||

| DM 49 | 7 | 100 | 100F | 49.30 | 65F | 150.10 | 5.30 | 1246.08 | 44.00 | 3/4" | 29.98 x 3.94 x 1.34 | 9.75 |

| 100F | 28.90 | 35F | 150.10 | 5.30 | 668.35 | 23.60 | 3/4" | 29.98 x 3.94 x 1.34 | 9.75 | |||

| 100F | 19.00 | -20F | 150.10 | 5.30 | 387.98 | 13.70 | 3/4" | 29.98 x 3.94 x 1.34 | 9.75 | |||

| DM 59 | 7 | 100 | 100F | 58.10 | 65F | 133.10 | 4.70 | 1512.29 | 53.40 | 11/2" | 31.30 x 5.74 x 1.89 | 20.00 |

| 100F | 35.50 | 35F | 181.25 | 6.40 | 824.11 | 29.10 | 11/2" | 31.30 x 5.74 x 1.89 | 20.00 | |||

| 100F | 23.50 | -20F | 181.25 | 6.40 | 484.27 | 17.10 | 11/2" | 31.30 x 5.74 x 1.89 | 20.00 | |||

| DM 89 | 7 | 100 | 100F | 89.50 | 65F | 266.21 | 9.40 | 2268.43 | 80.10 | 11/2" | 36.80 x 5.74 x 1.89 | 22.44 |

| 100F | 53.30 | 35F | 266.21 | 9.40 | 1243.25 | 43.90 | 11/2" | 36.80 x 5.74 x 1.89 | 22.44 | |||

| 100F | 35.30 | -20F | 266.21 | 9.40 | 733.49 | 25.90 | 11/2" | 36.80 x 5.74 x 1.89 | 22.44 | |||

| DM 116 | 7 | 100 | 100F | 116.00 | 65F | 368.16 | 13.00 | 2916.96 | 103.00 | 11/2" | 42.75 x 5.74 x 1.89 | 24.86 |

| 100F | 71.10 | 35F | 359.66 | 12.70 | 1653.89 | 58.40 | 11/2" | 42.75 x 5.74 x 1.89 | 24.86 | |||

| 100F | 46.80 | -20F | 356.83 | 12.60 | 968.54 | 34.20 | 11/2" | 42.75 x 5.74 x 1.89 | 24.86 | |||